Reference project WT241

University of Aalborg

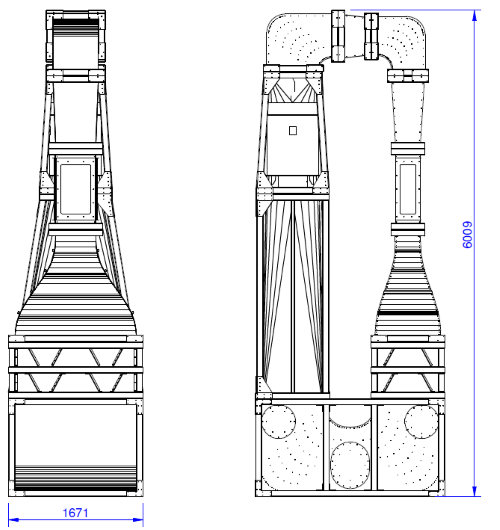

For the University of Aalborg in Denmark (Contact: Prof. Dr. Henrik Sørensen) the Windtunnel WT241 was built. The wind tunnel is characterized by a high contraction, the non-expanding corners as well as the long diffuser and high maximum speed.

Highlights

|

Product description

Basic stucture

The WT241 consists of a steel profile welded construction and galvanized sheet metal. The additional painting gives the wind tunnel an attractive appearance and is also protected against corrosion. Large manholes in the lower corners allow easy access to the inside of the wind tunnel.

Drive

The WT241 is driven by a vibration-decoupled axial fan. The fan, which is mounted on spring shock absorbers, is connected to the wind tunnel via canvas flanges.

Flow preparation

The diffusers, whose small opening angle counteracts flow separation, open into non-expanding corners. The wind tunnel has a large sieve chamber. This contains three sieves at an optimal distance from one another. These non-split stainless steel sieves are accessible via inspection flaps for easy cleaning. A honeycomb straightener with a length-to-diameter ratio of 8:1 further reduces the swirl of the flow. In a nozzle, the nozzle geometry of which corresponds to a polynomial of the fifth order, the flow is prepared and any turbulence that may be present is suppressed.

Measurement

The measurement in the wind tunnel takes place with the test section closed. The inside of the test section can be seen through glass windows. The recording of flow characteristics using optical measurement methods, e.g. PIV (Particle Image Velocimetry) or LDA (Laser Doppler Anemometry) is possible without any problems. The large corners located below the floor level offer low flow losses without restricting the working area around the test section.

Highlights

In the construction phase of the university, a recess in the foundation for the installation of a wind tunnel was planned. The task was to build a vertical wind tunnel, the test section of which is at the operator’s working height. The highest possible flow velocity should be generated in the given installation space. The wind tunnel fits within a few centimeters of the prepared space. The recess was subsequently covered with plates, which enables problem-free work directly on the measuring chamber.

Characteristics

| Design type | Closed loop, standing |

| Measuring cross section | 250 x 500 mm |

| Measuring length | 1000 mm |

| Top speed | 70 m/s |

| Turbulence level | 1 % |